Our goal is to provide you with an ergonomically-efficient design for your desired drive-thru restaurant business. While an architect might make a valiant attempt to layout your drive-thru restaurant, the fact is most lack the experience necessary to do that correctly. The designer of your space must not only understand what equipment will be necessary to produce your menu, but what the preparation procedures will be for each menu item. How many employees will need to be working at the same time to produce your menu items? What will each employee be responsible for? How will product flow through your kitchen during preparation and then to the service window? Where should each piece of equipment be placed so that employees can do their job in a logical linear progression, without their working paths being in conflict? And, where will you need open counter top space for ingredients, and for assembling and packaging items?

Ed Arvidson possess nearly 50-years of experience working in the foodservice industry. During that time he has designed restaurants, provided consulting services, taught classes and written books for aspiring restaurant owners, trained restaurants managers for major corporations, been a corporate food & beverage manager, owned and managed restaurants, tended bar, waited tables, cooked, bussed tables, and even washed dishes for his first job when he was 16-years old. He understands how restaurants work; how product should flow through a kitchen, how many people it will take to produce a menu, how the workload should be divided between them, and what equipment will be necessary. Ed is an Ergonomic Restaurant Designer, and that's what you need to start your drive-thru building design!

We will create the following drawings for you:

-

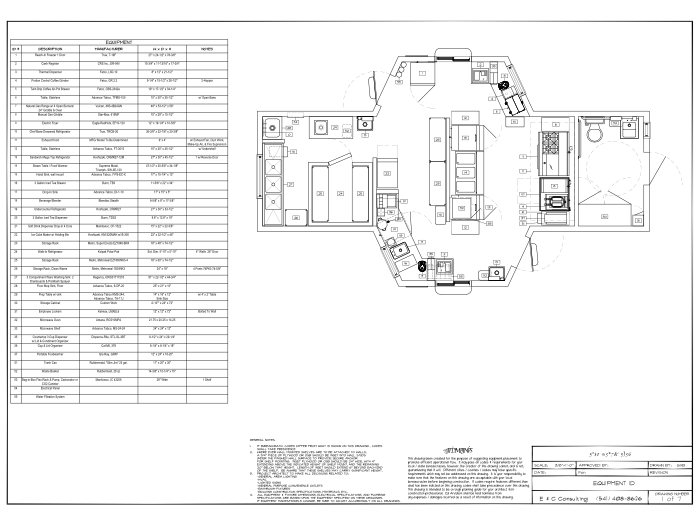

Equipment Floor Plan: This is a scale drawing of your future building showing all walls, doors, windows, cabinets, fixtures, and foodservice equipment.

All equipment will be identified by manufacturer and model number, and the manufacturer's specification sheet for each piece of equipment will be included with you finished drawings as PDFs. -

Overhead & Wall Shelving Floor Plan: This is an addendum to the Equipment Plan showing overhead shelving, and wall mounted shelving. Once again, manufacturer's specification sheet for each piece of equipment will be included with you finished drawings.

-

Critical Dimensions Floor Plan: This will show dimensions for the placement of all walls, doors, windows, and base cabinets.

-

Electrical Stub-Ins Floor Plans: This drawing will show the placement of all food service equipment-related electrical outlets, switches, junction boxes, circuits break box, etc. Dimensions will show linear placement of electrical features along the walls, and notes will indicate the height. Each electrical feature will be identified in an electrical schedule with a description of the equipment it will power, along with required volts, amps, and any special notes.

-

Plumbing Stub-Ins Floor Plan: This drawing will show the placement of all food service equipment-related plumbing features, faucets, drains (including floor sink drains), water heater, grease interceptor, etc. Dimensions will show linear placement of the above mentioned features along the walls. Dimensions will also be provided for the placement of features not stubbing out of walls, such as floor & floor sink drains, grease interceptor, etc. Each plumbing feature will be identified in a plumbing schedule with a description of the equipment it will supply, along with notes for special circumstances.

-

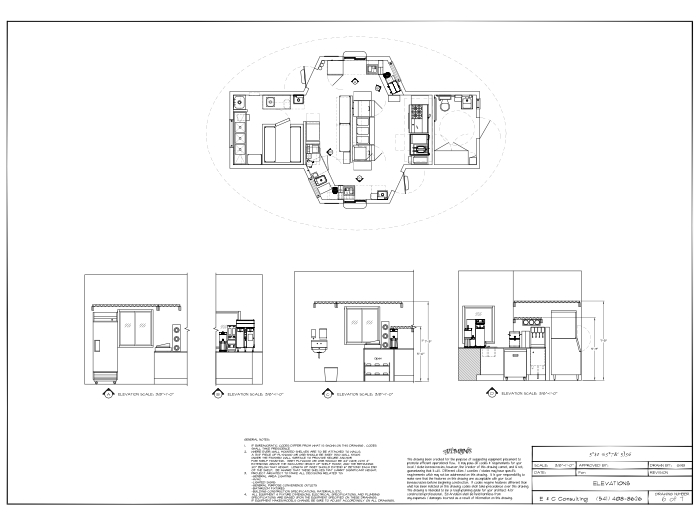

Interior Elevations Plan: This drawing will show what the interior of your drive-thru will look like. It will illustrate the placement of equipment, cabinets, and shelving in relationship to each other. It will also focus on those portions of your drive thru that incorporate custom cabinetry. These cabinet illustrations are not meant to be “shop drawings” for your cabinet contractor's fabrication purposes, but is intended to provide them with the information necessary for them to generate their own shop drawings. Features such as bays (open spaces under counter tops) for under counter refrigeration & trash receptacles, cup dispensers, drawers, and cabinet doors, along with needed dimensions will be provided.

All of our building designs strive to include the features that will be necessary for efficient operations, and meet bureaucratic requirements. In addition to the foodservice equipment & fixtures necessary to execute your menu, they also typically include: a small manager's administrative area (desk or office), security safe(s), alarm system, refrigerated and dry goods storage, employee's restroom/lockers, 3-compartment ware washing sink, hand washing sink(s), mop sink, food prep sink, sanitary air-gap floor sink drains & dipper wells (where required), grease interceptor, water heater, water filtration system (if necessary), exterior waste can enclosure, high quality insulated drive-up service window(s), and features required for ADA compliance.

All drawings and manufacturer's equipment & fixtures specification sheets will be provided as PDF files on a USB memory stick. We will also include the CAD file of your drawings for your architect's use, along with a letter of permission for the use of these drawings for modification, or duplication. You may take this memory stick to any blueprint shop or FedEx/Kinko's to have your drawings printed out in large-scale format.

Your Local ArchitectOnce you have the ergonomic design drawings that we have created for your business, you will need to take them to your local architect. We suggest using an experienced, reputable, local architect, because they will have an understanding of your local building requirements and accepted construction methods, and they'll also probably have a relationship with your local bureaucracies. The CAD file that we have provided for your architect's use should help simplify the process of producing the additional necessary drawings. Your architect will need to generate all the other drawings that will be necessary to satisfy your bureaucracies, and supply your contractor with the information necessary for construction. These may include the following:

- Plot plan/Site plan

- Utility excavation & installation plan

- Foundation plan

- Framing plan/details - including windows, doors, exterior siding, insulation, interior wall coverings (OSB/sheetrock/FRP).

- Electrical - Non-foodservice equipment related, such as general interior & exterior lighting (make sure interior lighting will meet the "lumens requirements" of your health department), signage, for HVAC, window and door air curtains (if required), general purpose interior & exterior electrical outlets, alarm system, etc. Electrical is to also include any menu board/intercom communication lines, and POS/remote monitors/printer lines.

- Plumbing - any additional required or desired plumbing, such as water closet and restroom hand sink, outdoor irrigation systems, interior fire sprinklers, etc.

- Roof Framing/Truss plan

- HVAC plan - we suggest Split Ventless Heating/Air Conditioning system

- Exterior Elevations

- Materials & finishes schedule

Throughout your planning and construction process, we will be available by phone or e-mail to assist you, your bureaucracy, architect, and contractor, with any needed clarifications, questions, or challenges.